Derivation of External Exposure Characteristics of Industrial Radiography Based on Empirical Evidence

Article information

Abstract

Background

This study aims to derive the characteristics of each work type for industrial radiography based on empirical evidence through expert advice and a survey of radiation workers of various types of industrial radiography.

Materials and Methods

According to a Korean report, work types of industrial radiography are classified into indoor tests, underground pipe tests, tests in a shielded room (radiographic testing [RT] room test), outdoor field tests, and outdoor large structure tests. For each work type, exposure geometry and radiation sources were mainly identified through the expert advice and workers’ survey as reliable empirical evidence.

Results and Discussion

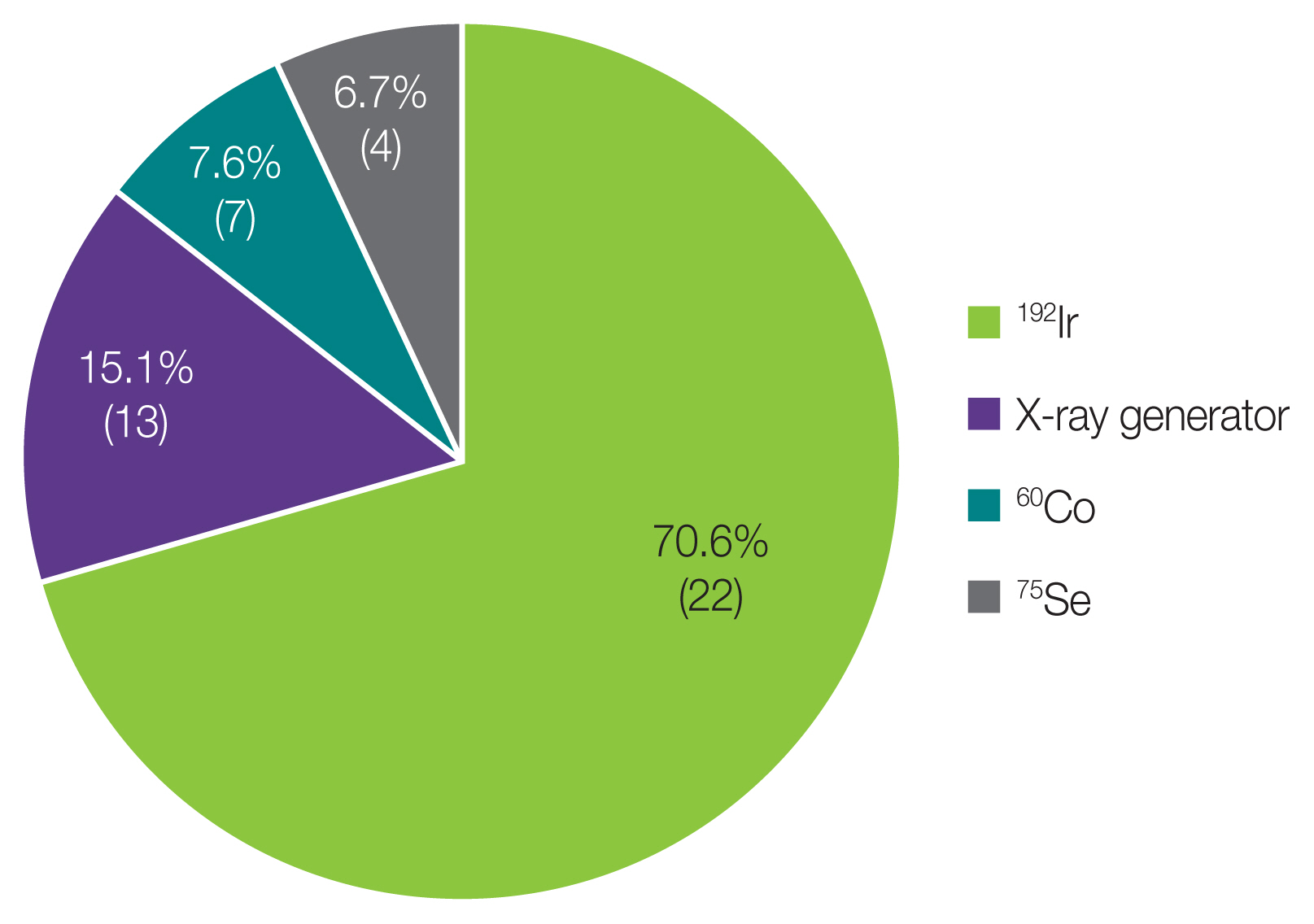

The expert advice and survey results were consistent as the proportion of the work types were high in the order of RT room test, outdoor large structure test, underground pipe test, outdoor field test, and indoor test. The outdoor large structure test is the highest exposure risk work type in the industrial radiography. In most types of industrial radiography, radiation workers generally used 192Ir as the main source. In the results of the survey, the portion of sources was high in the order of 192Ir, X-ray generator, 60Co, and 75Se. As the exposure geometry, the antero-posterior geometry is dominant, and the rotational and isotropic geometry should be also considered with the work type.

Conclusion

In this study, through expert advice and a survey, the external exposure characteristics for each work type of industrial radiography workers were derived. This information will be used in the reconstruction of organ dose for health effects assessment of Korean radiation workers.

Introduction

Non-destructive testing (NDT) is a method for inspecting the integrity or cracks in the objects without damaging or destroying them. These types of tests include radiography, magnetic particle testing, dye penetrant testing, ultrasonic flaw detection, eddy current, and electromagnetic testing [1–4]. Among these, radiography using ionizing radiation is one of the most widely used NDT methods, which is used by 53 out of 106 domestic NDT companies as of 2011 [5].

Despite its several advantages, industrial radiography has a drawback: the workers are exposed to the risk of radiation exposure during work. Radiation exposure by industrial radiography tends to be relatively high because the shielding conditions are not sufficient compared to other occupational exposures, such as nuclear power plant workers and radiation-related medical workers [6]. Likewise, in the 2018 report on occupational radiation exposures in Korea [7], it can be confirmed that industrial radiography has the highest average dose per person for 10 years from 2009 to 2018. In addition, according to the 2020 Nuclear safety yearbook [8], the annual personal dose (mSv/yr) is decreasing while the total number of radiation workers is increasing. However, the average annual dose (mSv/yr) of radiation workers in the industrial radiography field is still higher than that of radiation workers in other fields. Therefore, it is necessary to take extra priority for the radiation workers in the industrial radiography field to manage the radiation dose and its health effects in the radiation dose assessment system.

In the system of radiation dose assessment, the personal dose recorded in the legal dosimeter of radiation workers is reconstructed to each organ dose by using the dose conversion coefficient considering the exposure geometry and energy [9]. The long-term health effects assessment of radiation workers is then carried out by evaluating the effect of organ dose. With this procedure, an external exposure scenario is required that considers the energy of the source and the exposure geometry according to the situation of the worker.

Since now, various international studies have been conducted to establish the organ dose reconstruction methodology through exposure scenarios that consider the exposure characteristics of each type for nuclear power plants, medical, and industrial radiography works [10–13]. Based on these studies, a study was conducted in Korea to develop a representative external exposure scenario in the field of industrial radiography [14]. Though these studies made it possible to assess the health effects of radiation workers, it also has some limitations in that exposure characteristics are inevitably different due to differences in work environments, procedures, and regulations that are different for each country and work types.

Therefore, in this study, we attempted to derive the external exposure characteristics of industrial radiography radiation workers based on empirical evidence such as realistic work environments, procedures, and unknown customary practices for each type of industrial radiography to compensate for the limitations of the existing industrial radiography exposure scenario.

Materials and Methods

According to the reports of the Korea Institute of Nuclear Safety (KINS) and the Occupational Safety and Health Research Institute (OSHRI), the types of industrial radiography were classified into indoor tests, underground pipe tests, tests in a shielded room (radiographic testing [RT] room test), outdoor large structure tests, and outdoor field tests [5, 6]. The indoor tests and the RT room tests are distinguished in that the indoor tests are only for the immovable objects such as internal structures of plants, while the RT room tests are for the objects which can be moved into the RT room including castings and device parts. Outdoor large structure tests refer to works for facilities that require working at height, especially in large-scale outdoor structures such as immovable plant structures, pressure vessels, and steel bridges. Outdoor field tests are works performed on outdoor flat ground for the testing of outdoor structures including transport pipe and plant outdoor equipment. Radiation sources for industrial radiography are considered to be 60Co, 75Se, 137Cs, 169Yb, 170Tm, 192Ir, 226Ra, and X-ray generators, which have been reported in previous studies and reports [15–17]. The exposure geometry was divided into six types: antero-posterior (AP), postero-anterior (PA), left lateral (LLAT), right lateral (RLAT), rotational (ROT), and isotropic (ISO) as suggested in the International Commission on Radiological Protection (ICRP) Publication 116 [18], and shown in Fig. 1. The contents on the expert advice and a survey were all designed based on these types of industrial radiography work, radiation sources for industrial radiography, and exposure geometry during the irradiation.

In the case of the expert advice to understand the work characteristics of industrial radiography radiation workers, it was conducted on ten senior workers with more than 10 years of working experience in the industrial radiography field in various work types. The question for expert advice included items such as the radiation source used in each work type, the location of the radiation source during the irradiation, the trend of changes in the use of testing objects and sources over time, and the change in the characteristics of the industrial radiography field due to the revision of laws and regulations. The survey for radiation workers was conducted to secure the reliability and objectivity of information obtained through the expert advice from actual workers. This survey was conducted on 24 radiation workers at ten NDT companies to take into account various work types. The questions included the respondents’ starting years of the industrial radiography job, whether or not the radiation shield was worn, the location of the dosimeter during the working time, the usage proportion of the radiation sources and the workplace, and the location of radiation sources during the exposure were included. Work types and radiation sources were answered through multiple responses because these workers work in multiple workplaces and use multiple sources. Table 1 shows the main questions of the survey for radiation workers.

Results and Discussion

1. Characteristics of Work Types in Industrial Radiography

According to the expert advice, the work types in industrial radiography are divided into indoor tests, underground pipe tests, tests in a shielded room (RT room test), outdoor field tests, and outdoor large structure tests, as shown in the reports of KINS and OSHRI, and it was found that the collimators were used to reduce the unnecessary exposure in all work types. As most of the indoor tests have been replaced by the RT room tests, the proportion of the indoor tests has become very small (less than 10%). In addition, the underground pipe test showed relatively low exposure since the source was located under the ground and shielded with the soil and the additional lead shielding material. Likewise, it was found that relatively low exposure occurred in the RT room tests due to the concrete shielding and downward irradiation using a collimator. In the case of outdoor field tests, the proportion is also very low, as most of the movable objects are inspected inside the RT room. In addition, since it is possible to maintain a sufficient distance from the source and there is enough space for installing a shielding material in the outdoor field test, the exposure from the outdoor field tests is very low. On the other hand, in the outdoor large structure tests, since there is not enough space for installing the shielding material compared to the other work types and it is difficult to maintain a sufficient distance from the source due to the structure of the workspace, most of the exposures are considered to occur in these outdoor large structure tests.

Meanwhile, the trend of changes in the use of testing objects and sources over time was also investigated through expert advice. In Korea, a lot of underground pipe tests were carried out while laying many underground pipelines from the 1980s to the 2000s, and many outdoor large structure tests were also carried out since a lot of natural gas power plants were built as domestic coal and oil prices began to rise since early 2000s. In addition, some portion of industrial radiography work was conducted at night to minimize public exposure, and 30%–40% of night shifts of industrial radiography have recently been replaced by phased array ultrasonic testing (PAUT) which does not cause any radiation exposure. This might be considered as one of the reasons why the amount of radiation exposure of workers has been decreasing.

The results of the survey were consistent with the expert advice since the proportion of the work types was high in the order of RT room tests, outdoor large structure tests, underground pipe tests, outdoor field tests, and indoor tests, as shown in Fig. 2 (approximately 54.6%, 18.5%, 14.8%, 9.8%, and 2.3%, including multiple responses, respectively). Therefore, with the expert advice and the survey, it was shown that most of the work types were performed in the shielded RT room, and most of the exposures occur in outdoor large structure tests.

2. Characteristics of Radiation Sources in Industrial Radiography

According to expert advice, 192Ir, 60Co, 75Se, and X-ray generators were mainly used from the past to the present. Characteristics of radiation sources are summarized in Table 2. Among these radiation sources, 192Ir was generally used as the main source for most work types of industrial radiography, and 60Co and X-ray generators were often used outdoors before the revision of the law in 2014, but after the revision, these sources can be used only in RT rooms [19]. In the case of 75Se, since the energy is lower than that of 192Ir and 60Co, less shielding is needed and it is easier to shield workers. The use of 75Se began in the industrial radiography field around 2017 and is increasing due to the revision of the law in 2020, which enforced that only 75Se can be used for heat transport pipes and gas pipes less than 20 mm [19].

The survey showed a similar tendency to the expert advice. Including multiple responses, the proportion of radiation sources was high in the order of 192Ir, X-ray generators, 60Co, and 75Se, as shown in Fig. 3 (approximately 70.6%, 15.1%, 7.6%, 6.7%, and including multiple responses, respectively). Therefore, with the expert advice and the survey, it was confirmed that 192Ir was predominantly used, 60Co and X-ray generators were used only in RT rooms, and 75Se was used mostly in testing heat transport pipes and gas pipes.

3. Characteristics of the Exposure Geometry in Industrial Radiography

According to the expert advice, the radiation source of the industrial radiography usually exists in a shielded container. When the source should be used, the source is remotely moved to the testing spot using a crank [20]. Since there is no shielding between the source and the worker during this process, a significant portion of the exposure takes place in this process. In this perspective, the posture of the workers using this crank would be very important since the exposure geometry would be directly related to the exposure. However, experts explained that the posture of using the crank in this process varies depending on the convenience of the worker, thus the exposure geometry cannot be specified. However, we can expect that the exposure geometry is mostly AP or ROT. After the source reaches the testing spot, the exposure geometry may be checked through the position of the source during irradiation. At this time, since workers generally keep an eye on the testing spot and the source outside the radiation-controlled area, most of the exposures occur in the AP geometry.

In the case of work types except for the outdoor large structure tests and the underground pipe tests, radiation sources are located at the same horizontal level as the workers during irradiation. On the other hand, the sources are located not only at the same level as workers but also at the top and bottom in the case of the outdoor large structure tests and the underground pipe tests. Therefore, even in a situation where the AP geometry considering the location of the radiation source during irradiation is dominant because the worker watches over the testing site, the ROT geometry considering the use of cranks and movement of workers should be taken into account in work types except for the outdoor large structure tests and the underground pipe tests, and the ISO geometry considering the characteristics of work types should be considered in the outdoor large structure tests and the underground pipe tests.

In the results of the survey, 87% of workers, regardless of the work type, showed a tendency to coincide with the expert advice as the radiation source was located in front of them during the irradiation. Therefore, based on expert advice and research results, the AP geometry prevails during the irradiation, but depending on the type of work, the ROT or ISO geometry should also be considered.

There are two major limitations of this study: an insufficient sample size and ambiguous work types. The survey was conducted with a relatively small sample size, even though we tried to include workers who have worked in various work types. Furthermore, pipes of power plants installed outdoors can be included in both the outdoor large structure tests and the outdoor field tests. For this reason, depending on the respondents, it is possible that they answered with either the outdoor large structure tests or the outdoor field tests. The reason why the proportion of the outdoor large structure tests is relatively low and that of the outdoor field tests is relatively high is thought to be due to this confusion.

Despite the limitation, this study has its own strength as for the first time in Korea, external exposure characteristics were derived based on empirical evidence. Moreover, although the small sample size was used in this study, robust external exposure characteristics were derived thanks to consistent responses from workers with various work types. For statistical evidence, it is planned to conduct an additional survey of radiation workers with a larger sample size. Based on the derived external exposure characteristics, the external exposure scenario of radiation workers in industrial radiography could be reinforced.

Conclusion

In this study, the external exposure characteristics for each work type of industrial radiography radiation workers were derived through the expert advice and the survey of workers. Even though the proportion of RT room tests is the highest, the external exposure risk of the outdoor large structure tests is the highest compared to other work types. Therefore, this work type is the most important for the development of the external exposure scenarios. Also, the main radiation source considered in the exposure scenario is 192Ir with an average energy of 0.38 MeV. During irradiation, the exposure geometry should be considered as AP and ISO geometries for the outdoor large structure tests and underground pipe tests, and the AP and ROT geometries for all other work types. This information will be used to reconstruct organ dose for Korean radiation worker health effects assessment.

Notes

Conflict of Interest

No potential conflict of interest relevant to this article was reported.

Author Contributions

Conceptualization: Chung Y, Kwon TE. Methodology: Chung Y, Cho J, Kim E. Formal analysis: Cho J, Kim E. Funding acquisition: Chung Y, Kwon TE. Project administration: Chung Y, Cho J. Visualization: Cho J, Kim E. Writing - original draft: Cho J, Kim E. Writing - review and editing: Chung Y. Approval of final manuscript: all authors.

Acknowledgements

This study was supported by a grant of the Korea Institute of Radiological and Medical Sciences (KIRAMS), funded by the Nuclear Safety and Security Commission (NSSC), Republic of Korea (No. 50091-2021).