Lee and Kim: Considerations of the Optimized Protective Action Distance to Meet the Korean Protective Action Guides Following Maximum Hypothesis Accidents of Major KAERI Nuclear Facilities

Abstract

Background

Korea Atomic Energy Research Institute (KAERI) operates several nuclear research facilities licensed by Nuclear Safety and Security Commission (NSSC). The emergency preparedness requirements, GSR Part 7, by International Atomic Energy Agency (IAEA) request protection strategy based on the hazard assessment that is not applied in Korea.

Materials and Methods

In developing the protection strategy, it is important to consider an accident scenario and its consequence. KAERI has tried the hazard assessment based on a hypothesis accident scenario for the major nuclear facilities. During the assessment, the safety analysis report of the related facilities was reviewed, the simulation using MELCOR, MACCS2 code was implemented based on a considered accident scenario of each facility, and the international guidance was considered.

Results and Discussion

The results of the optimized protective actions were 300 m evacuation and 800 m sheltering for the High-Flux Advanced Neutron Application Reactor (HANARO), the evacuation to radius 50 m, the sheltering 400 m for post-irradiation examination facility (PIEF), 100 m evacuation or sheltering for HANARO fuel fabrication plant (HFFP) facility.

Conclusion

The results of the optimized protective actions and its distances for the KAERI facilities for the maximum postulated accidents were considered in establishing the emergency plan and procedures and implementing an emergency exercise for the KAERI facilities.

Keywords: Protective Measures, Emergency Preparedness, Nuclear Facilities

Introduction

The Korea Atomic Energy Research Institute (KAERI) operates nuclear research facilities licensed by the Nuclear Safety and Security Commission (NSSC), which requires a nuclear emergency plan. One of the purposes of the nuclear emergency plan is to protect the workers and the public during a nuclear emergency. The publication of the International Commission on Radiological Protection (ICRP) in 2007 recommends the reference level in the range of 20 to 100 mSv (acute or annual) in terms of the residual dose during the emergency exposure situation following a nuclear accident [ 1]. The protection strategy should be developed to meet the reference level, 20 to 100 mSv, as the residual dose for the emergency exposure situation at the preparedness stage [ 1]. To develop the protection strategy, the hazard assessment must be implemented to identify the area where the projected dose is higher than the reference level during an emergency exposure situation. The protection strategy including sheltering, evacuation and stable iodine administration, etc., should be developed to lower the dose below the reference level during the emergency exposure situation. After ICRP 2007 recommendation, the International Atomic Energy Agency (IAEA) developed the updated Emergency Preparedness and Response (EPR) requirement that is General Safety Requirement No. GSR Part 7, to follow the ICRP 2007 recommendation for the emergency exposure situation [ 2]. The GSR Part 7 suggests generic criteria (GC) to meet the ICRP reference level, and IAEA also developed revised operational intervention levels (OILs) as a part of the protection strategy to respond to a severe accident at a nuclear power plant (NPP) [ 3]. The revised OILs can be used for other nuclear facilities besides NPP but are not completely suitable for other facilities, because the OILs are calculated based on the source-term of NPP, which is different from other facilities. Recently, KAERI has been studying to develop a protection strategy for its own facilities. As part of these studies, KAERI considered the optimized protective active distance to meet the Korean protective action guides following maximum hypothesis accidents (MHA) of major KAERI facilities.

Materials and Methods

1. KAERI Nuclear Facilities and its MHA

1) Introduction of major KAERI nuclear facilities

KAERI operates various nuclear research facilities, but this paper only considers the major facilities which are important in the point of view of environmental impact following an accident. The first major facility is a nuclear research reactor, the High-Flux Advanced Neutron Application Reactor (HANARO), which is the open pool type and has 30 MW thermal power. The depth of the HANARO pool from pool surface to the upper part of the core is more than 12 m. The HANARO reactor core consists of 20 of 36-rod-assemblies and 12 of 18-rod-assemblies [ 4]. The second major facility is a post- irradiation examination facility (PIEF) which is composed of a pool for receiving, storing and dismantling the NPP spent fuel, and a hot-cell for test and examination of the spent fuel. The PIEF can handle spent fuels cooled for more than 6 months according to the license [ 5]. The third major facility is the HANARO fuel fabrication plant (HFFP). The HFFP handles nuclear materials, which have various enrichment of 235U from depleted uranium to low enriched uranium of 19.75%. The HFFP has various types of uranium materials such as UO 2, U metal, U 3Si, and UMo [ 6].

2) Definition of MHA scenarios of KAERI facilities for emergency planning

Accident scenarios for emergency planning of KAERIŌĆÖs major facilities are defined through reviewing safety analysis reports of each related facility, accident cases from similar facilities of other countries. Finally defined accident scenarios are summarized as shown in Table 1 [ 4ŌĆō 9].

2. MHA Source-Term Evaluation

1) Definition of source-term equation factors

To evaluate the environmental impact after an accident, the source-term representing the released amount of radioactive materials to the environment must be evaluated first. Normally, the source-term can be calculated by the Equation (1): where,

MAR: material-at-risk (the amount of radionuclides, in units of curies or grams, available to be acted on by a given physical stress), DR: damage ratio (the fraction of MAR impacted by the accident-generated condition, dimensionless), ARF: airborne release fraction (the coefficient used to estimate the amount of a radioactive material suspended in air as an aerosol and thus available for transport, dimensionless), RF: respirable fraction (the fraction of airborne radionuclides as particles that can be transported though air and inhaled into the human respiratory system, dimensionless), and LPF: leak path factor (the fraction of the radionuclides in the aerosol transported to the environment, dimensionless).

To calculate the source-term, each factor of the above equation must be defined first. The MAR was decided by referring to the Safety Analysis Report (SAR) and operation status of the related facility, and examples of similar facilities. The DR and the RF were selected as 100% to consider the worst case. The ARF was selected by referring to the US Nuclear Regulatory Commission (NRC) document including source-term evaluation. But the LPF is a building-specific value, so the LPF must be selected by considering facility operation conditions, activities of the responder during an accident, and building structure. The details of the LPF of the PIEF and the HFFF were described in the next section, but the LPF of HANARO followed its SAR. Finally, each factor of the source-term equation was selected, as shown in Table 2 [ 8ŌĆō 13].

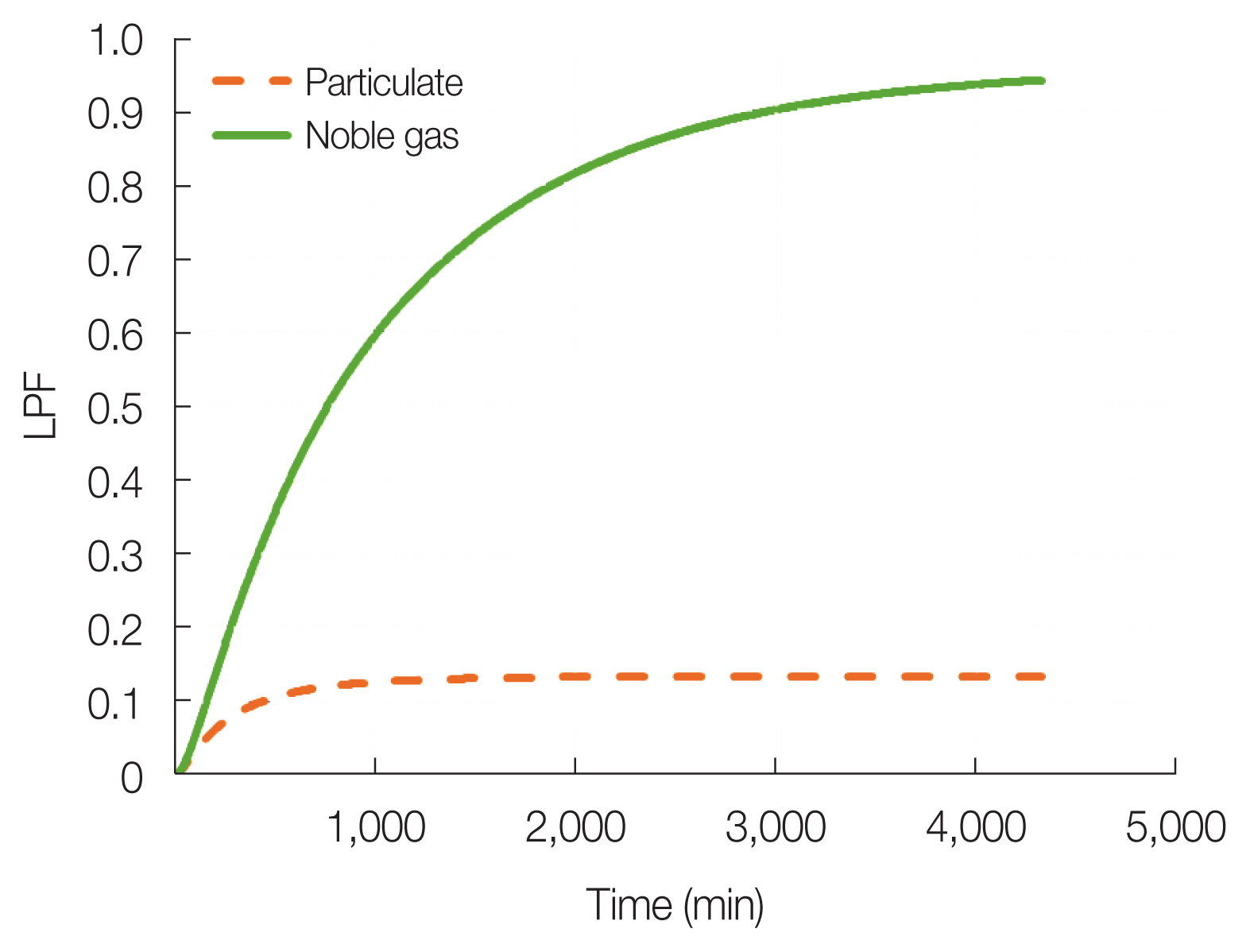

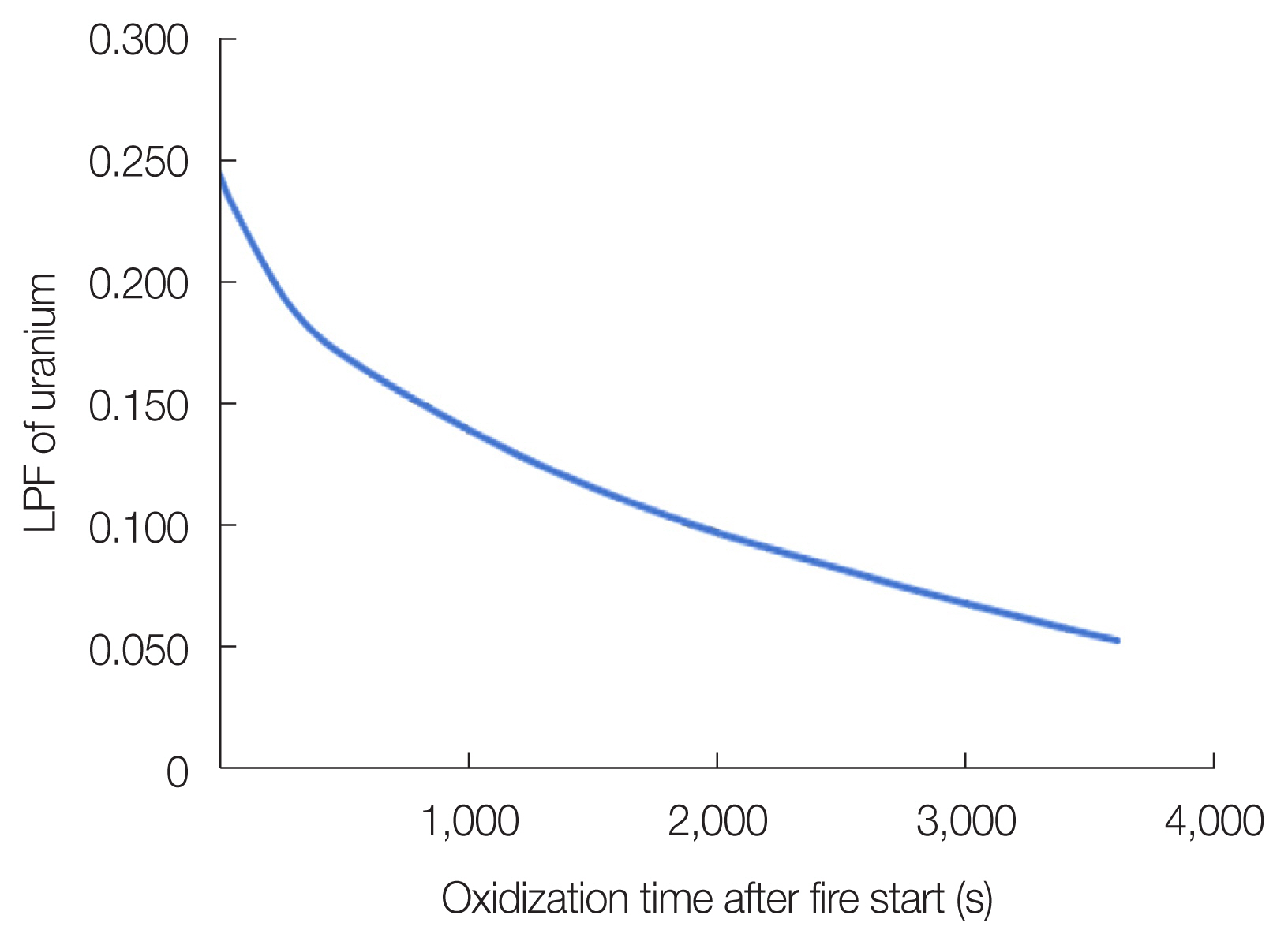

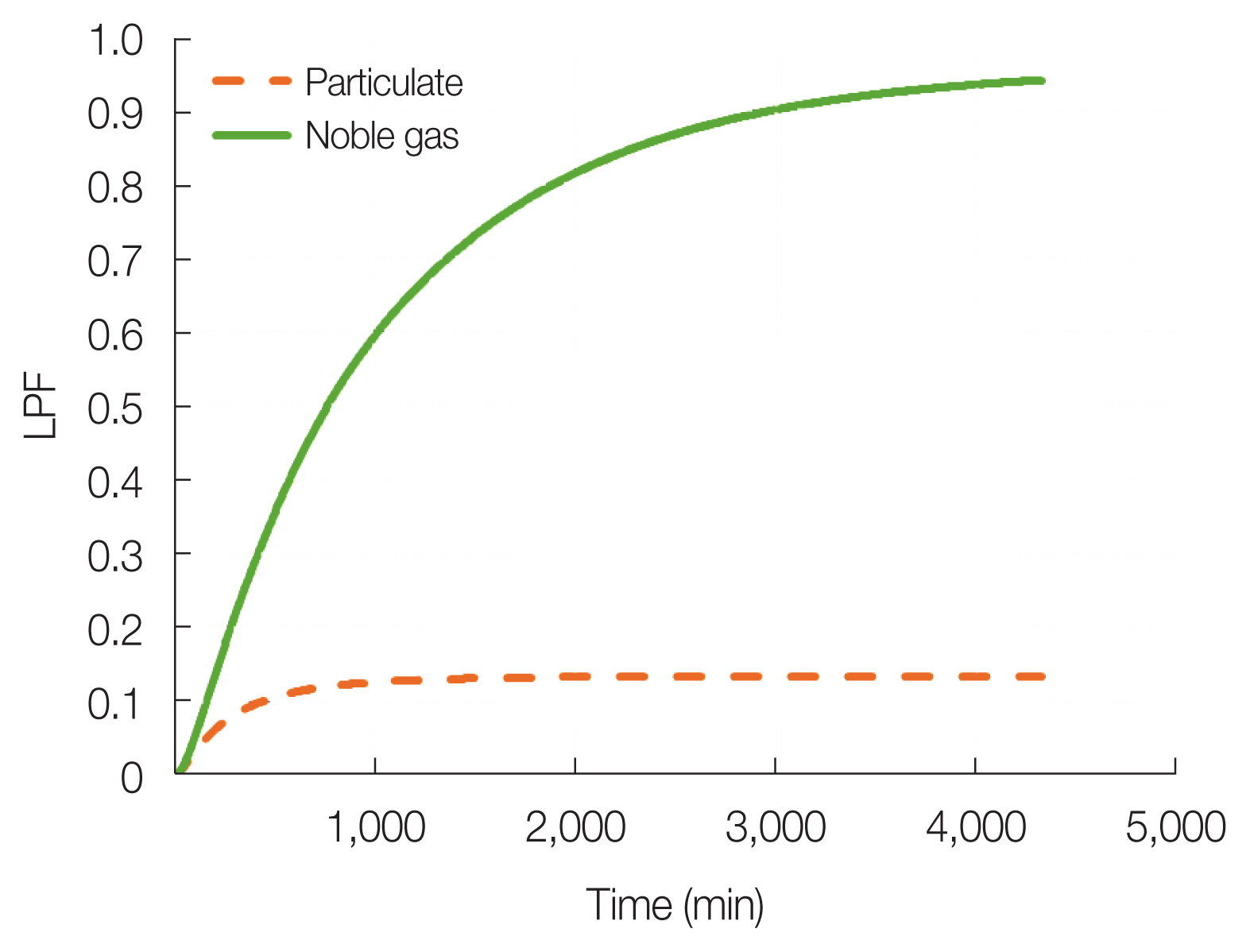

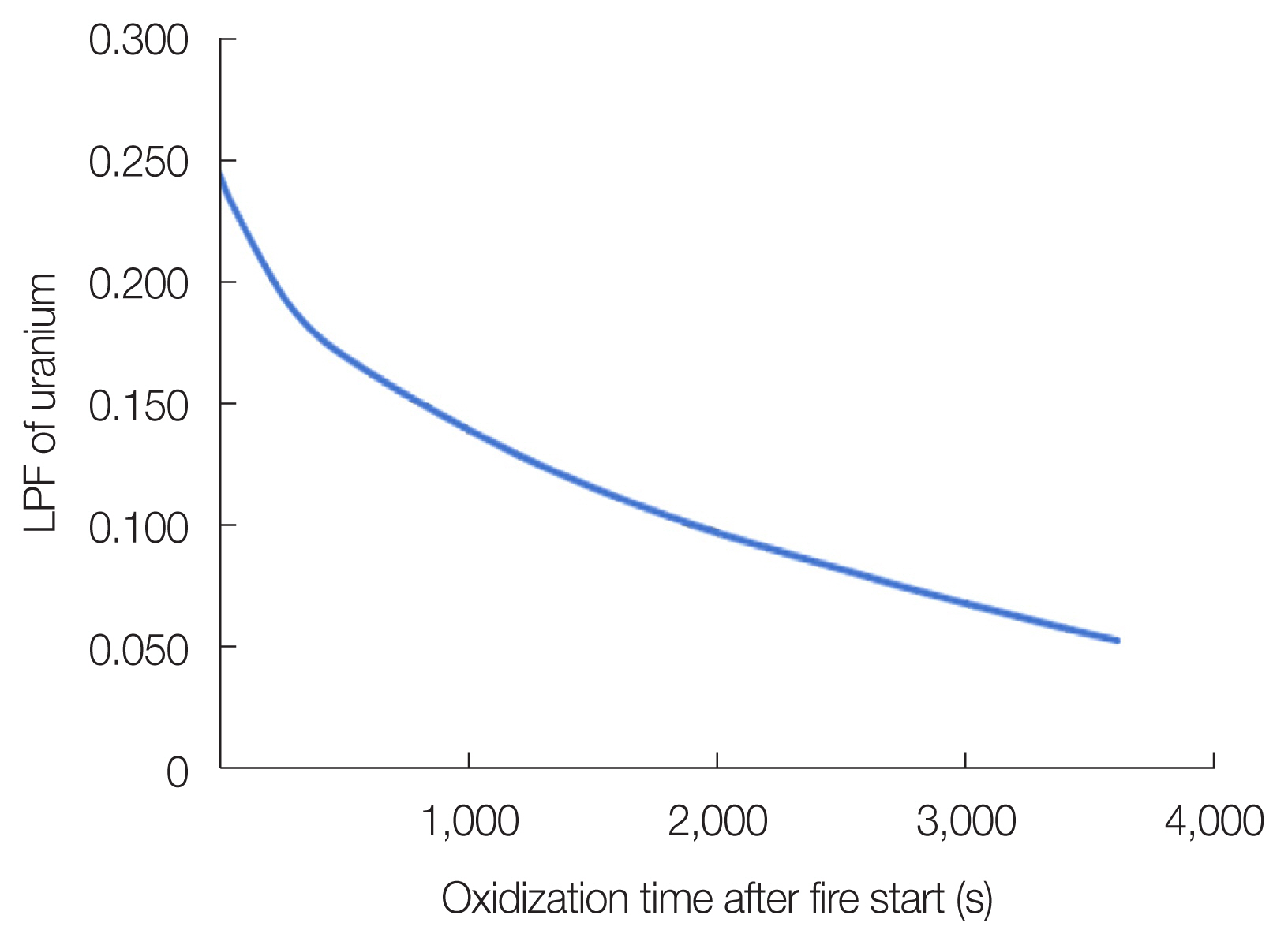

2) LPF calculation

If radioactive materials are released through the ventilation system, which means stack release, from the KAERI facilities during an accident, the environmental impact will not be severe because of diffusion at high altitude. However, if an accident occurs in a nuclear facility, the operator will try to confine the radioactive materials in the facility, and also the public does not accept the stack release during an accident. So the ground release by building leakage is considered during an accident. The driving force of building leakage is the positive pressure inside the building by any reason like fire or explosion, and the negative pressure outside the building by high wind speed. The US Department of Energy (DOE) suggested guidance to calculate the LPF by building leakage following an accident by MELCOR code [ 14]. The LPF of the PIEF and the HFFP by building leakage was calculated according to the DOE guidance. To calculate the LPF, first, each building structure was analyzed based on the design drawing, second, the MELCOR input data was developed to simulate the building, and, finally accident scenario was designed by the MELCOR input data. The major driving force in building leakage was wind speed for the PIEF, heat and wind speed for the HFFP. The LPF for the PIEF was calculated as shown in Fig. 1 and chosen as 0.95 for noble gas and 0.13 for particulate. To calculate the driving force by wind speed for the PIEF, the observed data at 10 m height of the meteorological tower at the KAERI site was analyzed and 5 m/s, which was the maximum average value of 10 minutes, was chosen. The wind speed of 5 m/s was changed into atmospheric pressure for the MELCOR input data. The standard ISO fire conditions were simulated in HFFP. According to the experiments by US DOE, the ignition time of uranium materials depends on the type of uranium materials. The HFFP has various types of uranium materials such as powder, bar, sintered body, rod, etc., but it can be broadly classified into two types: uranium powder or bar. The experiment data of US DOE shows the ignition temperatures according to the specific area of uranium [ 15]. Following the data, the ignition temperature of the powder in the HFFP that has specific area of about 14 cm 2/g is estimated to be about 400 ┬░C. The experiment also says that the uranium particles in the respirable size (10 ╬╝m aerodynamic equivalent diameter and less) were made airborne when the uranium bars were exposed to the temperature exceeding 500 ┬░C for more than 30 minutes [ 15]. Considering the standard ISO fire conditions, 400 ┬░C can be reached in 90 seconds, and 500 ┬░C can be reached in 3 minutes after a fire occurs. Since the powder can diffuse immediately after ignition, so the 90 seconds was considered the LPF application time for the powder. But the uranium bar needs 33 minutes to make the airborne particles in the fire, therefore, considering 7 minutes spare time, the 40 minutes, that is 2,400 seconds, was considered the LPF application time for the uranium bar. The LPF according to the ignition time was simulated as shown in Fig. 2, and 0.218 at 90 seconds from the ignition start time for the powder, and 0.085 at 2,400 seconds from the ignition start time for the bar were chosen to consider the uranium types in the HFFF.

3. Environmental Impact Assessment

The public protective actions are implemented in the area where the projected dose is greater than the Protective Action Guides (PAGs). In addition, protective action distances can be established to include the area which needs protective actions during emergency exposure situation. To find out this area, the environmental impact assessment should be implemented. The environmental impact due to the release of radioactive materials depends on the weather conditions, and an accident can occur at any time, and the weather conditions can change from day to day. The MACCS2 is a computer code for calculating environmental impact and uses 1-year weather conditions, so it can produce the calculation results as the value of the mean, 50 th, and 99.5 th percentile, and peak [ 16]. The environmental impact was calculated by the MACCS2 code based on the source term mentioned in the previous section. When applying the source term, the plume heat which can be included in each plume segment and can give a plume rise effect was not considered for conservative calculation, but the building dimension was considered for the calculation of the building wake effect. For the calculation, the observed meteorological data for 1 year at 10 m height of the meteorological tower of the KAERI site was used as the input data to simulate the ground release, and the 7-day exposure period was considered because the PAG for the urgent protective actions considers the dose within 7 days. The exposure pathways considered during this period are cloudshine, groundshine, and resuspension inhalation. In the MACCS2 code, the internal exposures consist of inhalation (from the plume and resuspension) and ingestion (not considered in this calculation), and the external exposures are from cloudshine, groundshine and skin deposition. The protective actions, such as sheltering and evacuation as an emergency response, were considered in the calculation. The calculated results as the peak value of the total effective dose by distance without the protective actions were shown in Fig. 3 for the MHA of the major KAERI facilities.

Results and Discussion

The results of the environmental impact assessment were reviewed by considering Korean PAGs, which are 10 mSv during 2 days for indoor sheltering, 50 mSv during 7 days for evacuation, and the residual dose after protective action by MACCS2. Through the review, the optimized protection distances for the facilities were established as shown in Table 3. When implementing each protective action for the considered distance in Table 3, the maximum residual effective doses over a period of up to 7 days were calculated as 14.7 mSv, 9.83 mSv, and 4.2 mSv for HANARO, PIEF, and HFFP, respectively. The residual doses are less than the PAG of the evacuation, 50 mSv, therefore, it can be seen that these protective actions and the distances are appropriate.

Conclusion

The optimized protective actions and the distances for the KAERI facilities against the maximum postulated accidents were assessed based on the PAGs described in the Emergency Preparedness Act of NSSC. These results were considered in establishing the emergency plan and procedures and implementing an emergency exercise for the KAERI facilities. Recent ICRP recommendations and IAEA requirements for the emergency exposure situation have been changed in applying the PAGs in the levels and the methodologies, but the Korean regulation follows the recommendations and requirements of the past. To follow the new international recommendations and requirements, continuous improvement is required in this field.

Acknowledgements

This study has been conducted as a part of the project of nuclear emergency preparedness of KAERI.

References

1. International Commission on Radiological Protection. The 2007 Recommendations of the International Commission on Radiological Protection. ICRP publication 103. Ann ICRP. 2007;37(2ŌĆō4):1-332.

2. International Atomic Energy Agency. Preparedness and response for a nuclear or radiological emergency (IAEA Safety Standards No GSR Part 7). Vienna, Austria, International Atomic Energy Agency. 2015.

3. International Atomic Energy Agency. Operational intervention levels for reactor emergencies and methodology for their derivation. Vienna, Austria, International Atomic Energy Agency. 2017.

4. Korea Atomic Energy Research Institute. HANARO Safety analysis report. Daejeon, Korea, Korea Atomic Energy Research Institute. 2017.

5. Korea Atomic Energy Research Institute. PIEF Safety analysis report. Daejeon, Korea, Korea Atomic Energy Research Institute. 2009.

6. Korea Atomic Energy Research Institute. HANARO Safety analysis report. Daejeon, Korea, Korea Atomic Energy Research Institute. 2000.

7. Lee G, Kim J, Lee H, Kim B. Analysis of the effectiveness of an emergency response scenario in case of HANARO design basis accident using MACCS2 code (KAERI/TR-5495/2014). Daejeon, Korea, Korea Atomic Energy Research Institute. 2014.

8. Lee G, Kim B, Lee H, Kim J, Choi P, Kang M, et al. Accident analysis of post irradiation examination facility (PIEF) for the emergency preparedness (KAERI/TR-6394/2016). Daejeon, Korea, Korea Atomic Energy Research Institute. 2016.

9. Lee G, Kim B, Lee H, Kim J. Radiation effects analysis of HANARO nuclear fuel fabrication facility after a fire accident for the radiation emergency preparedness (KAERI/TR-5976/2015). Daejeon, Korea, Korea Atomic Energy Research Institute. 2015.

10. DiNunno JJ, Anderson FD, Baker RE, Waterfield RL. Calculation of distance factors for power and test reactor sites (No. TID-14844). Washington, DC, Division of Licensing and Regulation of the Atomic Energy Commission. 1962.

11. Soffer L, Burson SB, Ferrell CM, Lee RY, Ridgely JN. Accident source terms for light-water nuclear power plants (No. NUREG-1465). Washington, DC, Nuclear Regulatory Commission. 1995.

12. Travis RJ, Davis RE, Grove EJ, Azarm MA. A safety and regulatory assessment of generic BWR and PWR permanently shutdown nuclear power plants (No. NUREG/CR-6451). Washington, DC, Nuclear Regulatory Commission. 1997.

13. US Nuclear Regulatory Commission. RASCAL 3.0: Description of Models and Methods (No. NUREG-1741). Washington, DC, US Nuclear Regulatory Commission. 2001.

15. US Department of Energy. Airborne release fractions/rates and respirable fractions for nonreactor nuclear facilities [Internet]. Washington, DC, US Department of Energy; 1994 [cited 2022 Jun 25]. Available from: https://www.nrc.gov/docs/ML1307/ML13078A031.pdf

16. Chanin D, Young ML. Code manual for MACCS2: Volume 1, userŌĆÖs guide (No. NUREG/CR-6613). Washington, DC, Nuclear Regulatory Commission. 1997.

Fig.┬Ā1

Leak path factor (LPF) by building leakage of the post-irradiation examination facility (PIEF).

Fig.┬Ā2

Leak path factor (LPF) by building leakage of HANARO fuel fabrication plant (HFFP).

Fig.┬Ā3

Total effective dose for each source term at HANARO, post-irradiation examination facility (PIEF), and HANARO fuel fabrication plant (HFFP).

Table┬Ā1

MHA Scenarios Considered for Emergency Planning at KAERI Facilities

|

Facility |

Operation condition |

MHA scenario |

|

HANARO |

Normal operation at 30 MWth

|

A movable foreign substance was in the primary cooling system. |

|

The foreign substance blocked one flow channel for cooling of a 36-rods fuel assembly. |

|

The 36-rods fuel assembly was melted because of the loss of flow. |

|

Alarm at pool top radiation monitor was occurred and emergency ventilation system was activated. |

|

The operator stopped ventilation system to block the environmental release of radioactive materials when the derived release limit was exceeded. |

|

Fission products in reactor hall were released through design building leakage forced by wind pressure. |

|

|

PIEF |

Operator handles NPP spent fuel assembly in pool |

17├Ś17 NPP spent fuel assembly was fallen by a mistake of operator during handling it in pool. |

|

The fallen assembly was damaged. |

|

Volatile fission products were released from the spent fuel to the pool area through pool water. |

|

The operator stopped ventilation system to block environmental release of radioactive materials when the derived release limit was exceeded. |

|

Fission products in pool area were released through building leakage forced by wind pressure. |

|

|

HFFP |

Fabrication process of HANARO fuel and experiment using hydrogen gas are ongoing |

Hydrogen was leaked and exploded, so a fire broke out. |

|

The fire was spread through ventilation duct and cable to HFFP |

|

Assume that the fire at HFFP follows the Standard ISO cellulosic curve. |

|

Uranium materials in each type were affected by the fire. |

|

Volatilized uranium was released to the plant space. |

|

The operator stopped ventilation system to block environmental release of radioactive materials when the derived release limit was exceeded. |

|

Volatilized uranium in plant was released through building leakage forced by wind pressure. |

Table┬Ā2

Factors Selected for Calculating the Source-Term

|

Facility |

MAR |

DR |

ARF |

RF |

LPF |

|

HANARO |

Inventory of 36-rods fuel assembly |

1 |

1 for noble gases, 0.5 for I, Br according to TID-14844 [10] |

1 |

0.3 according to HANARO SAR |

|

0.3 for Cs and Rb according to the early in-vessel in NUREG-1465 [11] |

|

Decontamination factor 100 for I, Br, Cs, and Rb according to NUREG-1465 |

|

|

PIEF |

Inventory of 17├Ś17 NPP spent fuel assembly |

1 |

0.4 for NG, 0.03 for Cs, 0.001 for Te according to case 3 in NUREG/CR-6451 [12] |

1 |

Calculated by MELCOR [8, 9] |

|

|

HFFP |

U 230 kg |

1 |

0.001 for U according to RASCAL 3.0 (NUREG-1741) [13] |

1 |

Calculated by MELCOR [8, 9] |

Table┬Ā3

Protection Distance and Protective Actions for KAERI Facilities

|

Facility |

Protection distances (m) |

Protective actions |

|

HANARO |

300 |

Evacuation |

|

800 |

Indoor sheltering |

|

|

PIEF |

50 |

Evacuation |

|

400 |

Indoor sheltering |

|

|

HFFP |

100 |

Evacuation or indoor sheltering |

|

|